Water Cooling Channels Decrease 3D Printed Mold Tool's Cycle Time by 50% - Fortify

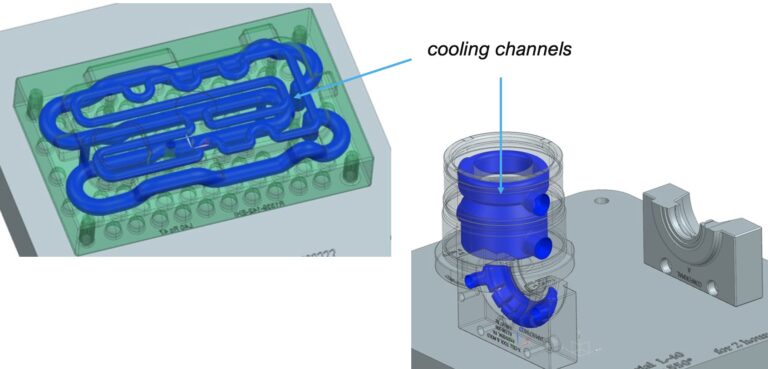

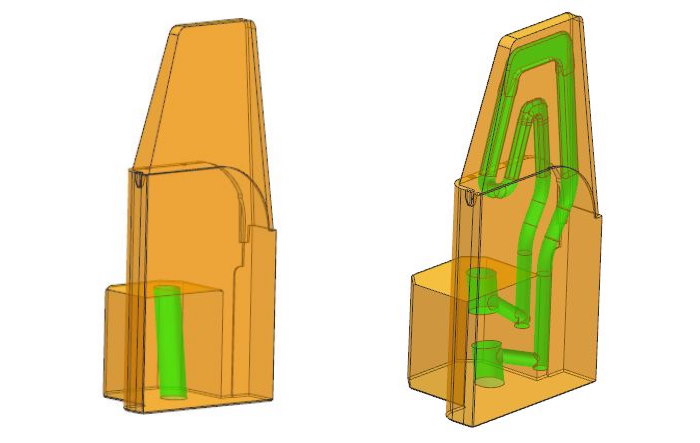

Fortify and PTC worked together to prove out if water cooling channels designed into the 3D printed mold tool could help reduce cycle time.

Conformal cooling: How Additive Manufacturing benefits injection moulding

Conformal Cooling: Higher-Quality Parts, Faster Injection Molding Cycle Times - SyBridge Technologies

3D Printed Inserts for Injection Molding

The American Mold Builder 2023 Issue 4 by petersonpublications - Issuu

Strategies To Modify the Surface and Bulk Properties of 3D-Printed Solid Scaffolds for Tissue Engineering Applications

Strategies To Modify the Surface and Bulk Properties of 3D-Printed Solid Scaffolds for Tissue Engineering Applications

Design and optimization of conformal cooling channels for injection molding: a review

Benjamin MacDonald on LinkedIn: #molddesign #moldmaking #additivemanufacturing #molds

Development of green conformal cooling channels for rapid tooling

Moldmaking Water-Flow Simulation Makes 3D-Printing Practical

Process Cooling Boosts Mold Efficiency

Additive manufacturing–assisted conformal cooling channels in mold manufacturing processes - Mahesh S Shinde, Kishor M Ashtankar, 2017

Effects of cooling channel layout on the cooling performance of rapid injection mold

A comprehensive review of injection mold cooling by using conformal cooling channels and thermally enhanced molds

/pic6847758.png)